Non-food industries

The non-food industry encompasses a wide range of sectors, each with unique challenges and requirements. From manufacturing and logistics to packaging and automation, we provide innovative solutions that enhance efficiency, reduce costs, and optimize operations. With a strong focus on quality, sustainability, and advanced technology, we help businesses improve processes, streamline workflows, and meet industry-specific demands.

Bag Handling

We design and manufacture transport systems for the efficient handling of filled or empty bags. Our conveyors are built to move bags steadily through your production environment — whether they need to be transferred, elevated, turned, or aligned for palletizing. We focus solely on the transport side of the process, ensuring a smooth, controlled flow between upstream and downstream equipment.

Bag Handling

Packaging

Our conveyor systems form the link between your packaging machines. Whether you're working with boxes, trays, pouches, or shrink-wrapped units, we provide reliable and precisely aligned transport. We don’t supply packaging machinery — we ensure your products get to and from it efficiently, with solutions that support spacing, buffering, and smooth line transitions.

Packaging HandlingIntralogistics

Efficient internal transport is key to productivity. Our intralogistics conveyors connect machines, departments, or storage zones across your facility. Whether moving crates, products, or packages over long distances or through tight spaces, we offer durable, low-maintenance systems tailored to your layout. We don’t handle storage or automation controls — just the movement between them.

Intralogistics

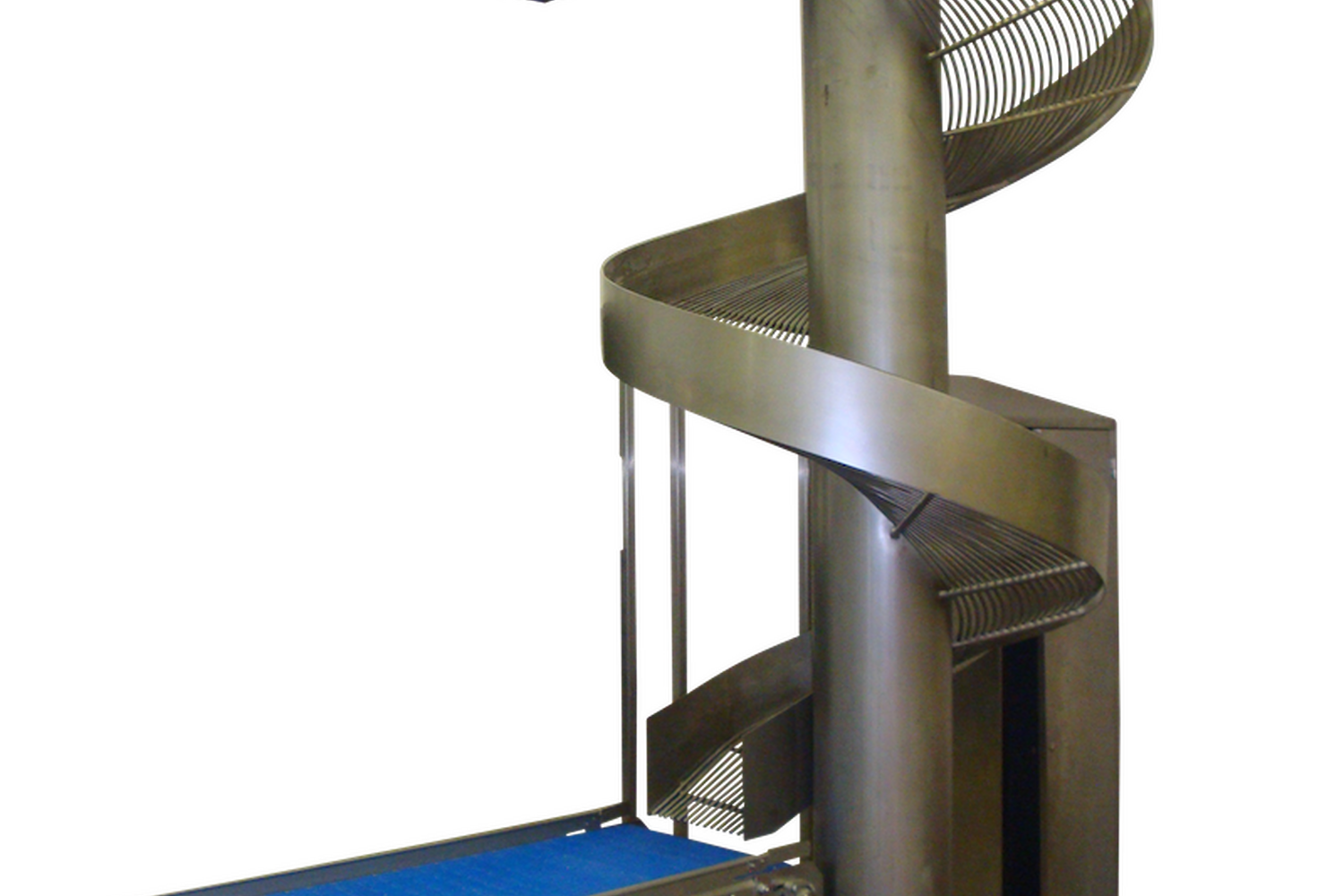

Buffering

In dynamic production environments, temporary storage between process steps is essential. Our buffering conveyors absorb fluctuations between machines or stations, helping to prevent downtime and maintain a consistent line flow. We build transport systems that are specifically designed to buffer and release products at the right pace — not to store them, but to keep your line running efficiently.

BufferingCrate Handling

Crates are a common carrier in both food and non-food sectors. We build transport systems for moving empty and full crates through washing areas, filling lines, or dispatch zones. Our conveyors are designed for stability, wash-down compatibility, and integration into existing logistics setups. We focus purely on crate transport — not the filling, stacking, or cleaning process.

Crate handling

Palletizing & De-palletizing

Jansen Conveyors supplies the transport systems that serve your palletizing or depalletizing robots. We ensure a stable, aligned product flow to and from the stacking point, using conveyors with centering, acceleration, or buffering functions. While we don’t build palletizers, we make sure your products reach them — and leave them — efficiently.

Palletizing & de-palletizingStacking & De-stacking

Our conveyor systems support automated stacking and de-stacking by ensuring consistent infeed and outfeed of trays, carriers, or crates. We don’t build the machines that stack — we build the systems that bring them product, and take it away again, in a steady and controlled flow. That’s how we help improve uptime and reduce manual handling.

Stacking-de-Stacking

Recycling

Recycling lines demand robust transport solutions. We supply conveyors that handle unsorted, heavy, or abrasive materials reliably and with minimal maintenance. Whether moving metals, plastics, or mixed waste between sorting steps, we deliver heavy-duty transport systems built to withstand harsh environments — always focused on material flow, never on processing or separation itself.

RecyclingRobotics

In modern production environments, robots are widely used for various handling tasks such as packaging, moving, sorting, and palletizing. These systems operate most efficiently when products are supplied in a constant and predictable flow. Jansen Conveyors provides conveyor systems that ensure a stable and efficient material flow within your automated processes, supporting smooth cooperation between robots, machines, and internal logistics.

Robotics

Don’t see your industry listed? Get in touch — we’re happy to discuss custom solutions for your specific needs.