Bag Handling

We focus on delivering efficient and flexible conveyor solutions for bag handling, ensuring smooth operations across various industries. Whether transporting, sorting, or stacking, our systems are designed to optimize your bag handling processes, enhancing productivity while reducing manual labor.

Robust transport foundation for bagging installations

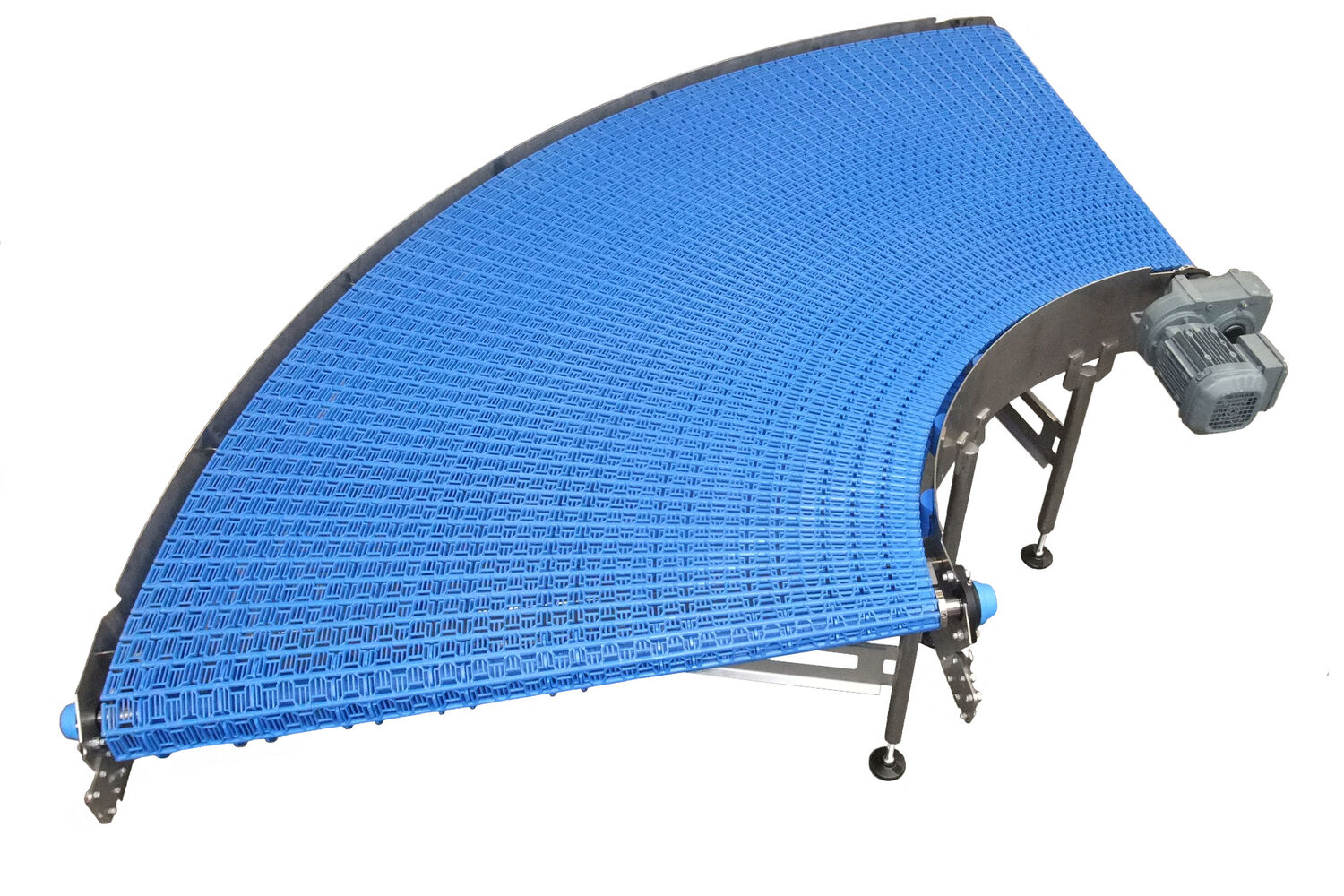

Bagging installations place high demands on conveying systems operating directly downstream of the bag filling machine. Filled bags with varying weights, changing product characteristics, and high dust exposure require a stable and reliable transport solution. Jansen Conveyors designs and manufactures conveyor lines and curves that are specifically tailored to these conditions. Our systems ensure controlled discharge of filled bags and provide a robust foundation for subsequent packaging and logistics processes.

Controlled transport of filled bags

After the bagging process, controlled conveying is essential to prevent product loss, bag damage, and disruptions within the line. Variations in bag size, fill level, and product properties require conveying solutions that minimize shocks and guide bags in a stable manner. By designing conveying systems based on product behavior, throughput, and interaction with bagging, weighing, and palletizing systems, we ensure smooth product flow and stable transitions between process steps. This increases process reliability and keeps the line manageable.

Durable constructions for dusty and intensive environments

Bagging installations often operate in dusty and industrially demanding environments. Depending on the application and product, conveying solutions are supplied in coated steel or stainless steel (SS). Wear-resistant components, structural rigidity, and maintenance-friendly detailing ensure a long service life and predictable maintenance. Open constructions reduce dust accumulation and facilitate inspection and cleaning, allowing the conveying system to remain a reliable and stable link within the complete bagging and packaging process.

What can we do for you?

We offer custom-made and efficient conveyor systems specifically designed for handling heavy bags, such as cement, sand, and other construction materials. Our systems are developed to ensure the smooth and reliable transportation of these heavy bags through every stage of your process, from loading and unloading to sorting and stacking.

When optimizing your bag handling operations, our systems ensure a streamlined workflow. By reducing bottlenecks and improving the flow of bags, we increase the efficiency of your logistical processes. Whether it's moving bags between various locations or transporting heavy bags within a production facility, our conveyor systems provide a solution tailored to your specific needs.

In addition, our automated solutions reduce the need for manual labor. This not only accelerates your operational processes but also lowers labor costs and enhances overall productivity. By eliminating the heavy lifting and carrying of bags, we create a more efficient and cost-effective working environment.

FAQ

What kind of materials are the belts made of?

The belts are made of POM and PA, on request we can send you the certifications.

What is the minimum and maximum temperatures the belts can handle?

Our belts can be used in temperatures between -40°/120C°.

The strength and load capacity of the belts are heavily influenced by the temperature, for every application we can make a calculation for you.

Can we use the belts at high speeds?

Yes, our Multi-Way belts can be used at high speeds, we have delivered belts who are being used at 100 meters a minute.

How long do the belts last?

This is depending on the situation, we have customers in the food industry who have been using the same belts for 10 years. But on the other hand we have belts in very abrasive environments were they “just” last a couple of years.

Is it possible to wet clean?

Yes, our stainless steel conveyors with hygienic design (foodsafe) can be cleaned with water.