Robotics

In modern production environments, robots are widely used for various handling tasks such as packaging, moving, sorting, and palletizing. These systems operate most efficiently when products are supplied in a constant and predictable flow. Jansen Conveyors provides conveyor systems that ensure a stable and efficient material flow within your automated processes, supporting smooth cooperation between robots, machines, and internal logistics.

Reliable Automation Solutions

Choosing the right conveying technology is crucial to choose the right conveying technology. Jansen Conveyors offers high-quality conveyor systems that are perfectly aligned with the requirements of robotic automation. From food-processing applications to other industries, our range ensures reliable infeed and outfeed of materials to and from robot cells.

Widely Applicable Across Multiple Sectors

In food processing, stainless-steel solutions ensure safe handling and easy cleaning. In packaging lines, precise and stable conveying paths contribute to a consistent product flow toward robots. For logistics and distribution, we supply systems designed for high throughput speeds, while in recycling, wear-resistant designs withstand intensive, rough handling.

Thanks to this sector-focused approach, our conveyor systems align perfectly with the technical and practical requirements of your robotic environment.

Why Our Conveyors Are Ideal for Robotic Automation

Robotic automation only works effectively when products are supplied in a consistent and predictable manner. That’s why our conveyors are built with a stable frame construction, precise guiding components, and reliable drive technology. This ensures that products are always presented in the same way—essential for robots operating with fixed cycle times and exact positions.

In addition, our designs take into account the specific requirements of a robot cell: correct heights, safe access zones, adequate distance from moving parts, and seamless integration with control systems. As a result, our systems align not only mechanically but also functionally with the overall process.

Thanks to this combination of stability, precision, and customization, our conveyors can work effortlessly alongside robots in a wide range of industries.

What can we do for you?

We support companies in the robotic automation industry with conveyor systems that guarantee continuity, stability, and safe infeed and outfeed of products. Our solutions increase the efficiency of a wide range of robotic applications by creating a consistent product flow and minimizing error-prone manual handling.

Whether it concerns food products, packaging, or other types of materials: we provide the conveyor solution that fits your process, environment, and level of automation.

FAQ

Is it possible to provide the belts with gripping modules?

For the MWCM and MX belt we have inserts as gripping modules and for the MWCU and the MWFT we can provide special insert, for example plastic blocks or stainless steel shafts.

Can we as original equipment manufacturer order belts and sprockets for our own conveyor systems?

Yes, this is possible we also deliver just belts and sprockets for manufacturers.

What kind of materials are the belts made of?

The belts are made of POM and PA, on request we can send you the certifications.

We are a original equipment manufacturer and we are interested in using the Multi-Way program, are the any special conditions for manufacturers?

Yes, this is always possible please contact us for more information.

What is the minimum and maximum temperatures the belts can handle?

Our belts can be used in temperatures between -40°/120C°.

The strength and load capacity of the belts are heavily influenced by the temperature, for every application we can make a calculation for you.

Can we use the belts at high speeds?

Yes, our Multi-Way belts can be used at high speeds, we have delivered belts who are being used at 100 meters a minute.

How long do the belts last?

This is depending on the situation, we have customers in the food industry who have been using the same belts for 10 years. But on the other hand we have belts in very abrasive environments were they “just” last a couple of years.

What are the delivery times for the belts?

The delivery times for the belts are approximately between three and five working days, urgent delivery is possible with consultation.

What are the specifications you need to make a quotation?

To request a quotation we need the following information from you:

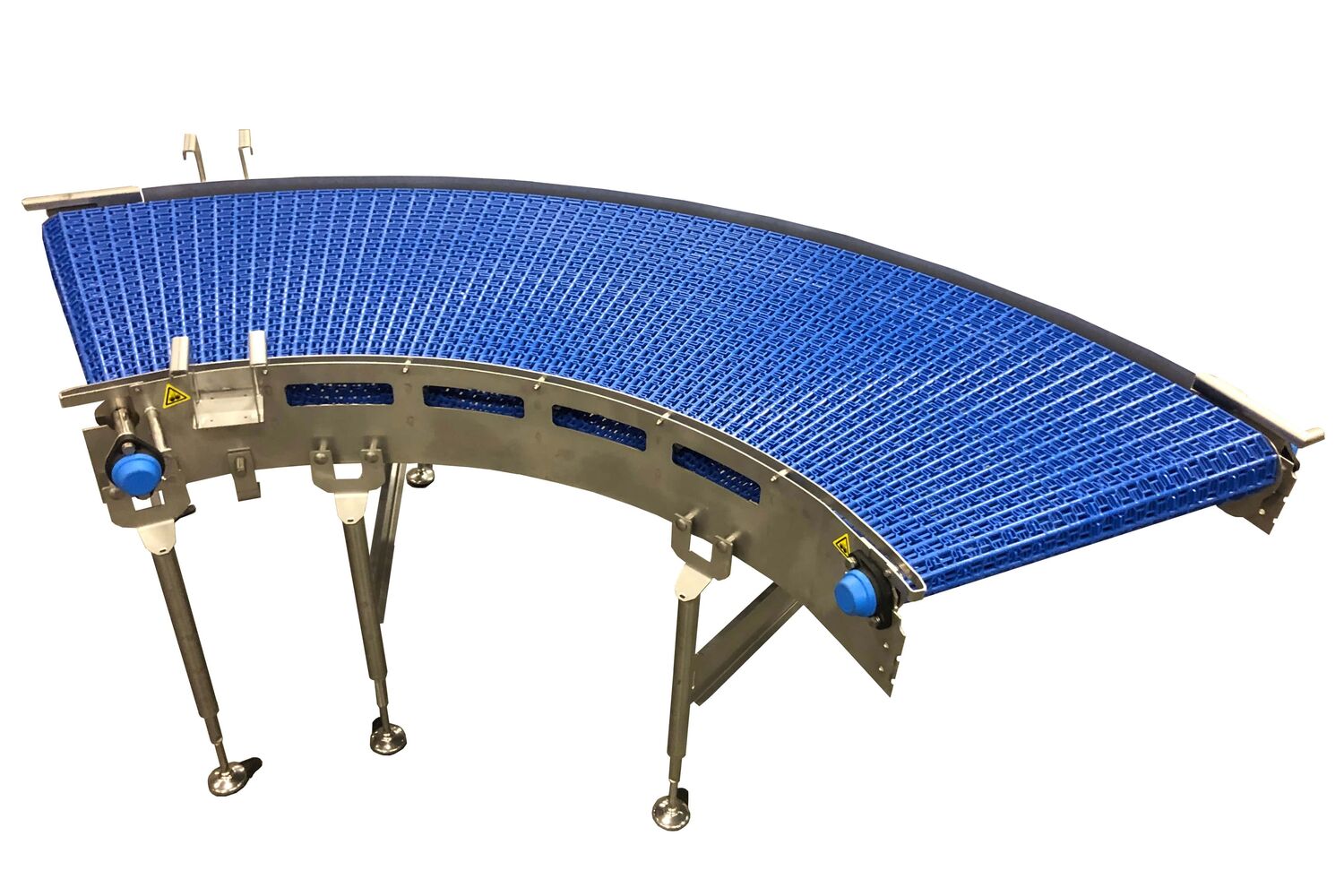

- Type of belt: Multi-Way Coarse Mesh (MWCM), Multi X, Multi-Way Flat Top (MWFT), Multi-Way Flat Top Perforated (MWFT Perf.), Multi-Way Curve Belt (MWCU)

- The belt width

- The belt length

- The speed what you request the conveyor to work at

- Information about the product you wish to convey like the measurements, weight etcetera.