Buffering

Buffering is a fundamental element of a stable intralogistics installation. In production and logistics processes, it is inevitable that different process steps operate at varying speeds, cycle times and levels of availability. Without buffering, these differences immediately become visible in the form of downtime, waiting times and loss of output. Jansen Conveyors develops buffer systems that temporarily store product flows, regulate them in a controlled manner and release them again at the right moment. This decouples processes from one another and keeps the overall line predictable, efficient and controllable. Our focus is fully on reliable buffering between processes, ensuring that disruptions remain local and do not propagate throughout the entire system.

Buffering as a means of process decoupling and capacity balancing

Buffers create a functional separation between process steps. When a machine slows down, is being changed over or temporarily stops, the buffer allows upstream and downstream processes to continue operating at their own optimal capacity. This increases the effective uptime of machines and prevents unnecessary restarts and operator interventions.

Jansen Conveyors designs buffer systems that do more than just add storage capacity. They also provide control over product sequencing, throughput speed and discharge. This results in a controlled material flow with reduced peak loads, less stress on the line and a more consistent output.

Broad applicability across various industries

- Food Processing

In food processing environments, buffering is essential to ensure stable interaction between process steps such as processing, inspection, cooling and packaging. Our hygienic stainless-steel buffer systems prevent product accumulation, minimize manual interventions and contribute to a consistent, food-safe process.

- Warehousing & Distribution

In warehouses and distribution centers, buffers absorb fluctuations in order flow and inbound and outbound logistics. They ensure a steady supply to sorting and picking processes and prevent peak moments from causing congestion or inefficient use of capacity.

- Industry & Assembly

In industrial and assembly environments, buffers compensate for differences in processing times, manual assembly operations and quality inspections. This ensures a continuous supply of components and prevents downtime of critical machines.

- Automation & Robotics

Within automated lines, buffers are indispensable as decoupling points between robot cells, AGVs and AMRs. They ensure product availability, make variations in cycle times manageable and increase the reliability of automated processes.

Why our buffer systems are so reliable

A buffer system must function predictably under varying loads. That is why Jansen Conveyors builds its buffers with stable frame constructions that limit vibrations and product damage, precise guidance for consistent product positioning, and reliable drive technology for smooth and controlled infeed and outfeed.

All buffer systems are fully custom-designed and tailored to product characteristics, required buffer capacity, layout, safety zones and maintenance accessibility. Through extensive integration with conveyor systems, machines and control systems, the overall installation remains stable, efficient and scalable.

What can we do for you?

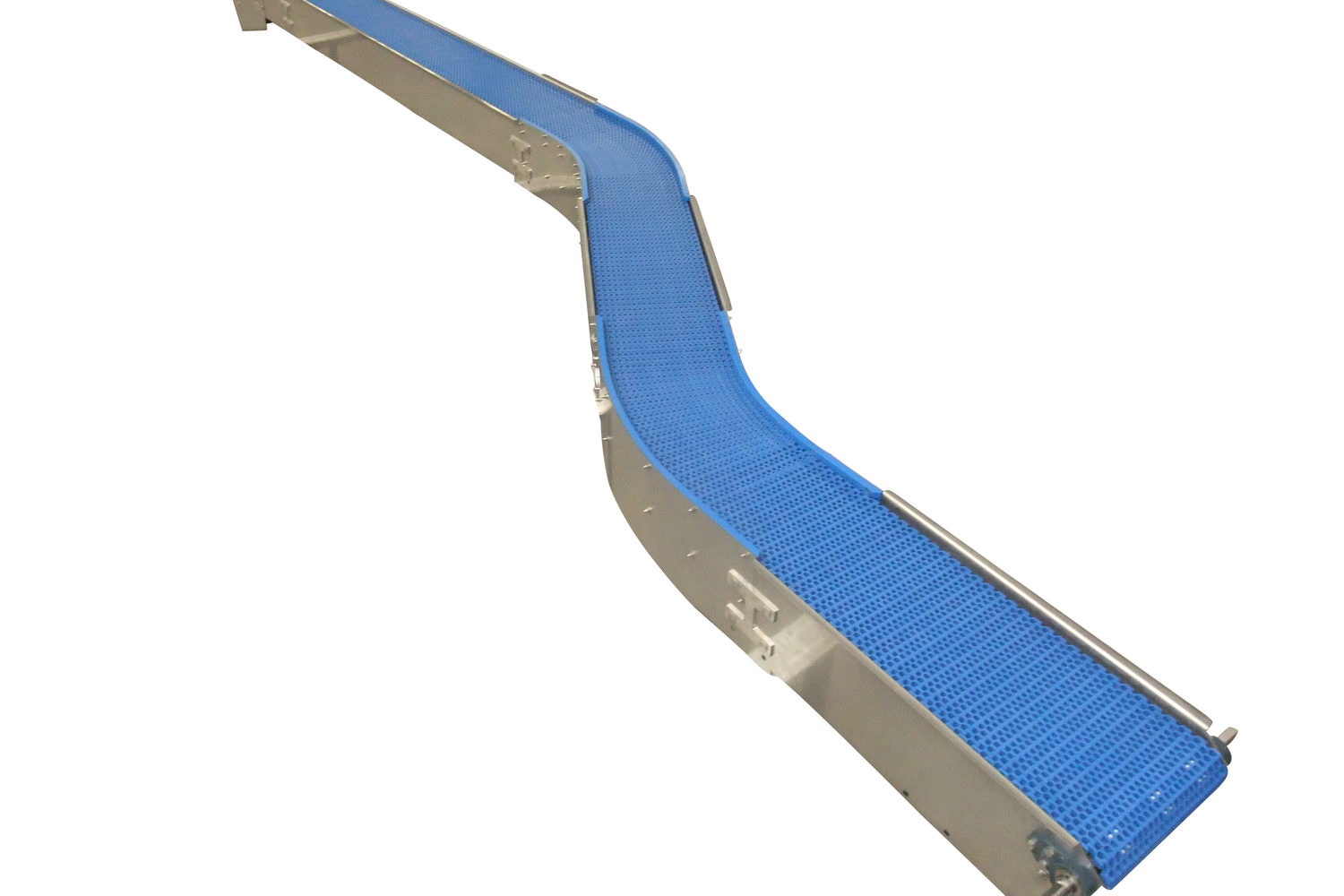

We specialize in providing high-quality conveyor belt solutions that can significantly enhance your buffering processes. Our custom transport systems can be the perfect addition to your operations. By integrating our conveyor systems, including curved conveyors for complex layouts, we help improve the flow and efficiency.

Our transport belts are designed to reduce bottlenecks, manage product flow effectively, and keep your operations running smoothly. With our solutions, you can ensure seamless transitions across different stages of production, minimizing downtime and increasing productivity. We focus on delivering flexible and reliable systems that are tailored to your specific needs, making us a valuable partner in optimizing your operations.

FAQ

Is it possible to provide the belts with gripping modules?

For the MWCM and MX belt we have inserts as gripping modules and for the MWCU and the MWFT we can provide special insert, for example plastic blocks or stainless steel shafts.

Can we as original equipment manufacturer order belts and sprockets for our own conveyor systems?

Yes, this is possible we also deliver just belts and sprockets for manufacturers.

We are a original equipment manufacturer and we are interested in using the Multi-Way program, are the any special conditions for manufacturers?

Yes, this is always possible please contact us for more information.

Can we use the belts at high speeds?

Yes, our Multi-Way belts can be used at high speeds, we have delivered belts who are being used at 100 meters a minute.

How long do the belts last?

This is depending on the situation, we have customers in the food industry who have been using the same belts for 10 years. But on the other hand we have belts in very abrasive environments were they “just” last a couple of years.

We are an original equipment manufacturer and we are interested in using the Multi-Way program, are the any special conditions for manufacturers?

Yes, this is always possible please contact us for more information.