Food industries

The food industry operates in a fast-paced and highly regulated environment where efficiency, hygiene, and reliability are key. Our solutions are designed to optimize your production processes, ensure compliance with industry standards, and enhance operational efficiency.

Meat processing

Conveyor systems in the meat industry must meet strict hygiene standards while maintaining high efficiency. We design stainless steel solutions for processing, portioning, packaging, and waste handling. Built for washdown environments and continuous operation, our systems ensure safe and reliable product flow

Meat processing

Egg handeling

Eggs require gentle and precise handling to prevent damage during transport. Our conveyor systems are designed to move eggs safely through grading, packing, and processing lines. With smooth transitions and controlled movement, we help maintain product quality while increasing throughput.

Egg handlingFruit & Vegetable Processing

Fresh produce demands careful handling and efficient flow. Our conveyor systems are designed to transport fruits and vegetables with minimal bruising or damage, whether for washing, sorting, packaging, or further processing. Built for hygiene and flexibility, they support high-capacity lines and fast changeovers.

Fruit & Vegetable Processing

Seafood Processing

Seafood processing requires robust and hygienic conveyor systems that perform reliably in wet, cold, and corrosive environments. Our stainless steel solutions are ideal for transporting fish, shellfish, and other seafood products through processing, weighing, and packaging stages — all while meeting strict hygiene and food safety standards.

Seafood ProcessingBeverage processing

Beverage production lines demand speed, precision, and cleanliness. Our conveyor systems are designed to handle bottles, cans, and cartons efficiently — from filling and labeling to packaging and palletizing. With smooth, high-capacity transport and options for automated routing and accumulation, we help streamline your production flow while maintaining hygiene and uptime.

Beverage processing

Fried Products

Fried products require careful handling to preserve texture and appearance. Our conveyor systems are designed to transport hot or delicate items such as snacks, patties, and coated products through cooling, inspection, and packaging processes. Built with food-grade materials and easy-to-clean designs, they support hygiene and consistent product quality in high-output environments.

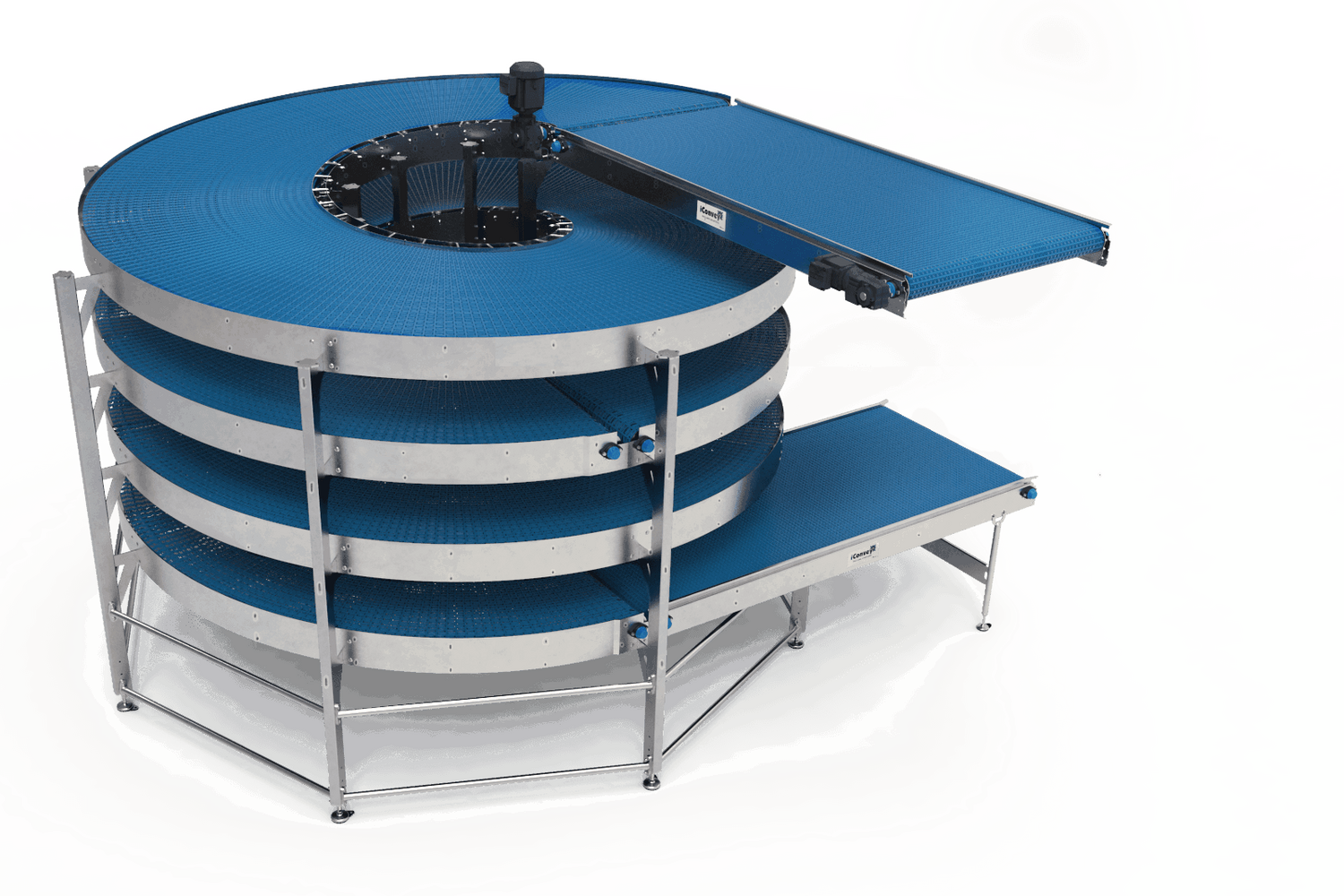

Fried ProductsCooling & Freezing

Conveyors in cooling and freezing applications must handle temperature extremes while maintaining product integrity and flow. Our systems are designed for use in chilled or frozen environments, supporting processes like inline cooling, spiral freezing, and product buffering. Built with stainless steel and food-grade materials, they ensure reliable operation under demanding conditions.

Cooling & Freezing

FDA-Certified Materials for Food Safety

In food processing environments, safety and compliance are non-negotiable. That’s why we use FDA-certified materials for all product-contact components, including belts, guides, and surfaces. These materials meet strict standards for hygiene, non-toxicity, and cleanability, ensuring your conveyor system is fully suitable for direct contact with food.

By combining FDA-approved components with hygienic design and high-quality stainless steel construction, we help you meet industry regulations and maintain product integrity throughout the entire process.

Don’t see your industry listed? Get in touch — we’re happy to discuss custom solutions for your specific needs.

Aegis Design Conveyor

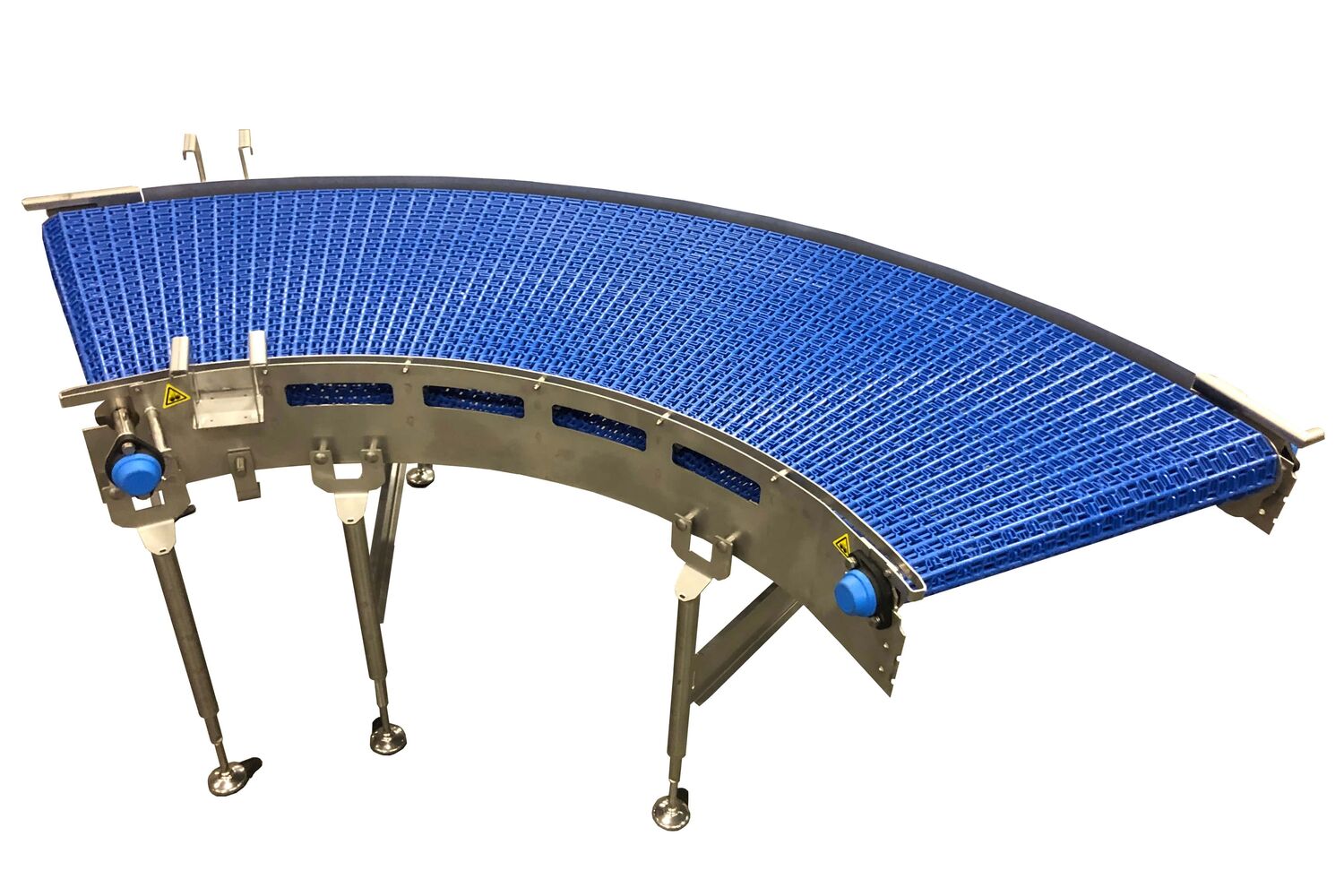

Our Aegis execution is developed for food environments where hygiene is critical. The design minimizes horizontal surfaces to prevent water and residue accumulation. We use NGI-certified hygienic bearings and components that meet the highest standards for clean design.

Side frames include strategic openings to allow full access during cleaning, reducing washdown time and improving overall food safety.

Multi-Way Curve Conveyor (hygienic design)

FAQ

Is it possible to provide the belts with gripping modules?

For the MWCM and MX belt we have inserts as gripping modules and for the MWCU and the MWFT we can provide special insert, for example plastic blocks or stainless steel shafts.

What kind of materials are the belts made of?

The belts are made of POM and PA, on request we can send you the certifications.

What is the minimum and maximum temperatures the belts can handle?

Our belts can be used in temperatures between -40°/120C°.

The strength and load capacity of the belts are heavily influenced by the temperature, for every application we can make a calculation for you.

Is it possible to wet clean?

Yes, our stainless steel conveyors with hygienic design (foodsafe) can be cleaned with water.

How can we clean the conveyor systems?

This is easily done with a brush or compressed air cleaning.

Are the conveyor systems easy to maintain?

Yes, our conveyor systems don’t require any special tools to maintain which makes it very easy to maintain.

Are the conveyor systems safe?

Yes, all our conveying systems meet the European requirements for safety.

In what kind of materials are the conveyors available?

The frame of the conveyor is available in stainless steel 304, on request stainless steel 316 and in steel powder coated in colour as requested by client.