Beverage processing

In the beverage processing industry, efficiency, hygiene, and precision are key to maintaining product quality and safety. Our conveyor systems are designed to meet the specific demands of beverage production, from handling raw ingredients to bottling and packaging. Using food-grade materials that are easy to clean and resistant to corrosion, our solutions ensure compliance with strict safety standards, such as FDA regulations.

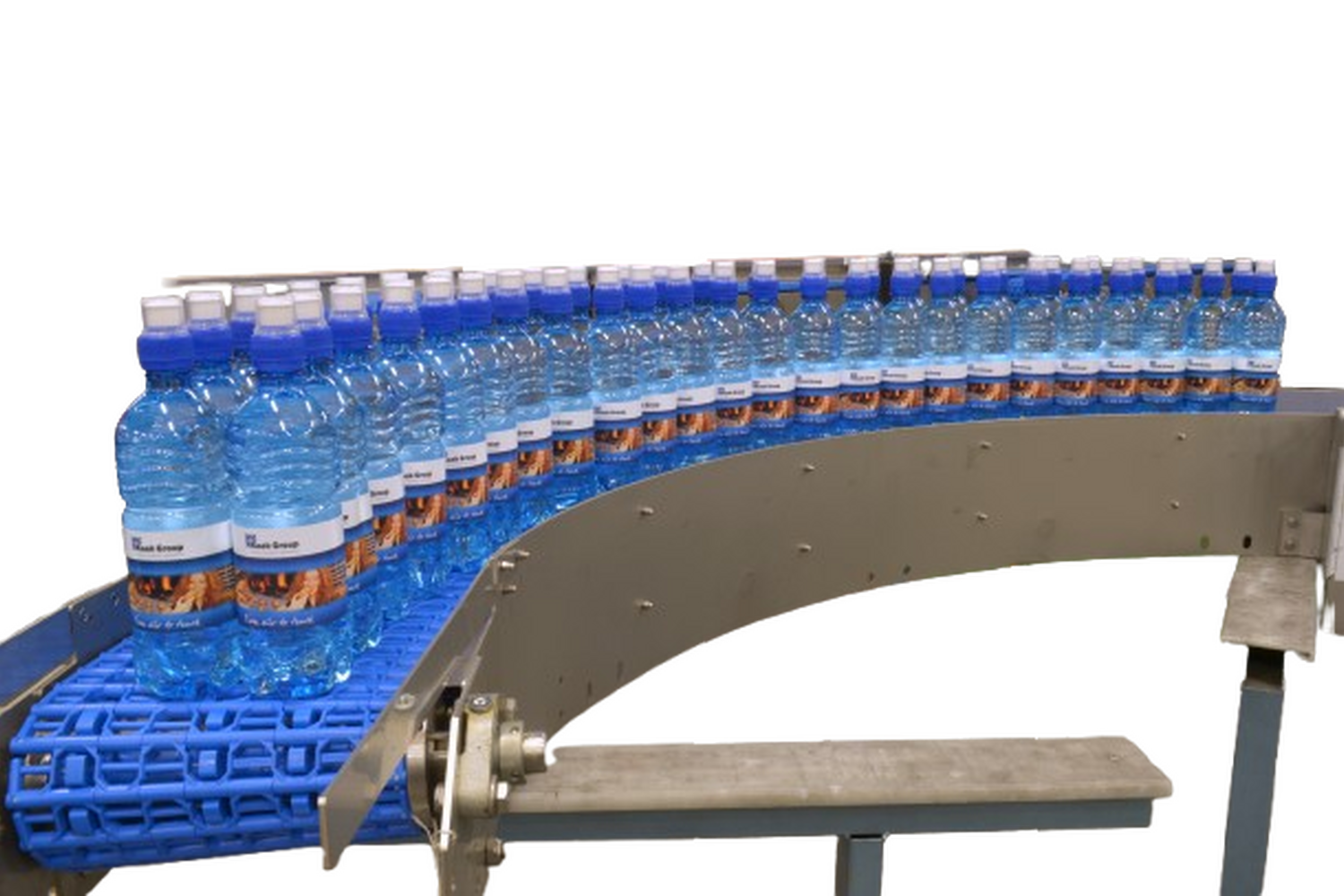

Hygienic curve solution

In beverage processing environments, ensuring a smooth, hygienic, and controlled product flow is crucial to maintain product integrity, avoid cross-contamination, and meet stringent food safety regulations. Our multi-way curve conveyor is specifically designed to offer flexible and space-saving routing between filling, labeling, capping, packaging, and palletizing stages.

This hygienic curve system allows bottles, cans, cartons, or other beverage containers to be redirected efficiently in multiple directions — ideal for production lines with several inspection stations, sorting points, or parallel packaging lines.

Constructed entirely from stainless steel and compatible with modular or flat-top belts, the curve is ideal for wet, clean-in-place (CIP), and washdown environments common in the beverage industry. Its open, easy-to-clean frame design complies with the highest hygiene standards, while ensuring safe and smooth transport of delicate or high-speed beverage containers. Whether you’re handling glass bottles, PET containers, tetra packs, or multipacks, this solution helps you optimize your plant layout while maintaining a reliable, efficient, and sanitary product flow.

Hygienic Design and our type belts

Our conveyors for beverage applications are constructed entirely from stainless steel (AISI 304 or 316), with a hygienic, open-frame design. Sloped surfaces, rounded edges, and minimal horizontal areas reduce contamination risks and make cleaning faster and more effective. We use NGI-certified hygienic components and bearings to ensure full compliance with industry hygiene standards.

What can we do for you?

We offer customized conveyor solutions specifically designed to optimize your beverage processing operations. Whether you need to streamline the handling of raw ingredients, enhance the efficiency of your bottling lines, or improve the packaging process, our conveyor systems are tailored to your needs. Our equipment is built using food-grade, FDA-compliant materials, ensuring the highest levels of hygiene and safety.

We also provide curved conveyors to maximize space and ensure smooth product flow, even in tight or complex layouts. By integrating our conveyor systems, you can boost productivity, reduce downtime, and maintain a seamless and reliable operation throughout your beverage production process.

FAQ

What is the minimum and maximum temperatures the belts can handle?

Our belts can be used in temperatures between -40°/120C°.

The strength and load capacity of the belts are heavily influenced by the temperature, for every application we can make a calculation for you.

Can we use the belts at high speeds?

Yes, our Multi-Way belts can be used at high speeds, we have delivered belts who are being used at 100 meters a minute.

Is it possible to wet clean?

Yes, our stainless steel conveyors with hygienic design (foodsafe) can be cleaned with water.

How can we clean the conveyor systems?

This is easily done with a brush or compressed air cleaning.

Can you deliver including the control system?

Yes, on request we can deliver our conveyor systems with a control system.