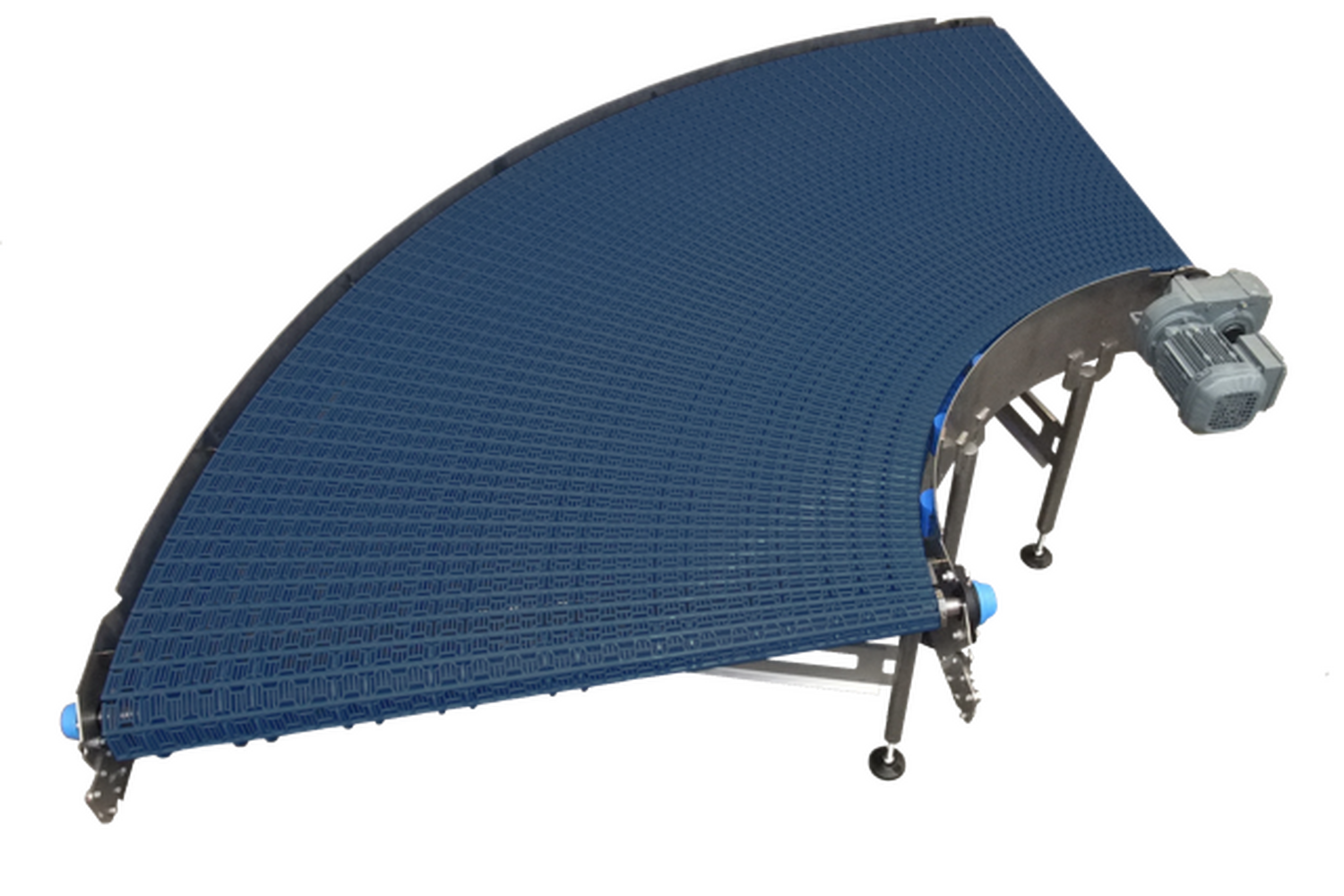

Curved conveyors

Our curved conveyors are engineered to maximize efficiency, particularly in environments with limited space. Our Multi-Way Curved Conveyor offers three fixed inner radius options—942, 767, and 600 mm—ensuring that even the widest conveyors maintain a compact radius. This makes our curved conveyors ideal for tight spaces, eliminating the need for additional in- and outlet sections and reducing the conveyor's footprint.

See moreA unique solution

Curved conveyors provide the perfect balance of compact design, hygiene, speed, and reliability. Whether you're in food processing, beverage production, or another industry requiring precise product handling, our curved conveyors are the ideal solution for maximizing space, maintaining product alignment, and ensuring efficient production processes.

Perfect for food processing

Our curved conveyors are specifically designed for the food processing industry, where hygiene and cleanliness are paramount. These conveyors are fully washable, with minimal horizontal surfaces and an open, "finger-safe" belt that ensures easy cleaning. All materials used are FDA-approved and food-safe, making our curved conveyors the best choice for handling baked goods, meats, and even product carriers such as boxes and crates.

Our hygienic design Curve Conveyor

Curved conveyors with a hygienic design are essential for industries requiring strict cleanliness, such as food processing and pharmaceuticals. These conveyors feature smooth, easy-to-clean surfaces, minimizing bacterial buildup and ensuring compliance with health and safety standards. Their durable plastic modular belts and open-frame structures make them ideal for maintaining high levels of hygiene. Hygienic curved conveyors enhance workflow efficiency while reducing downtime for cleaning, offering a reliable solution in material handling operations.

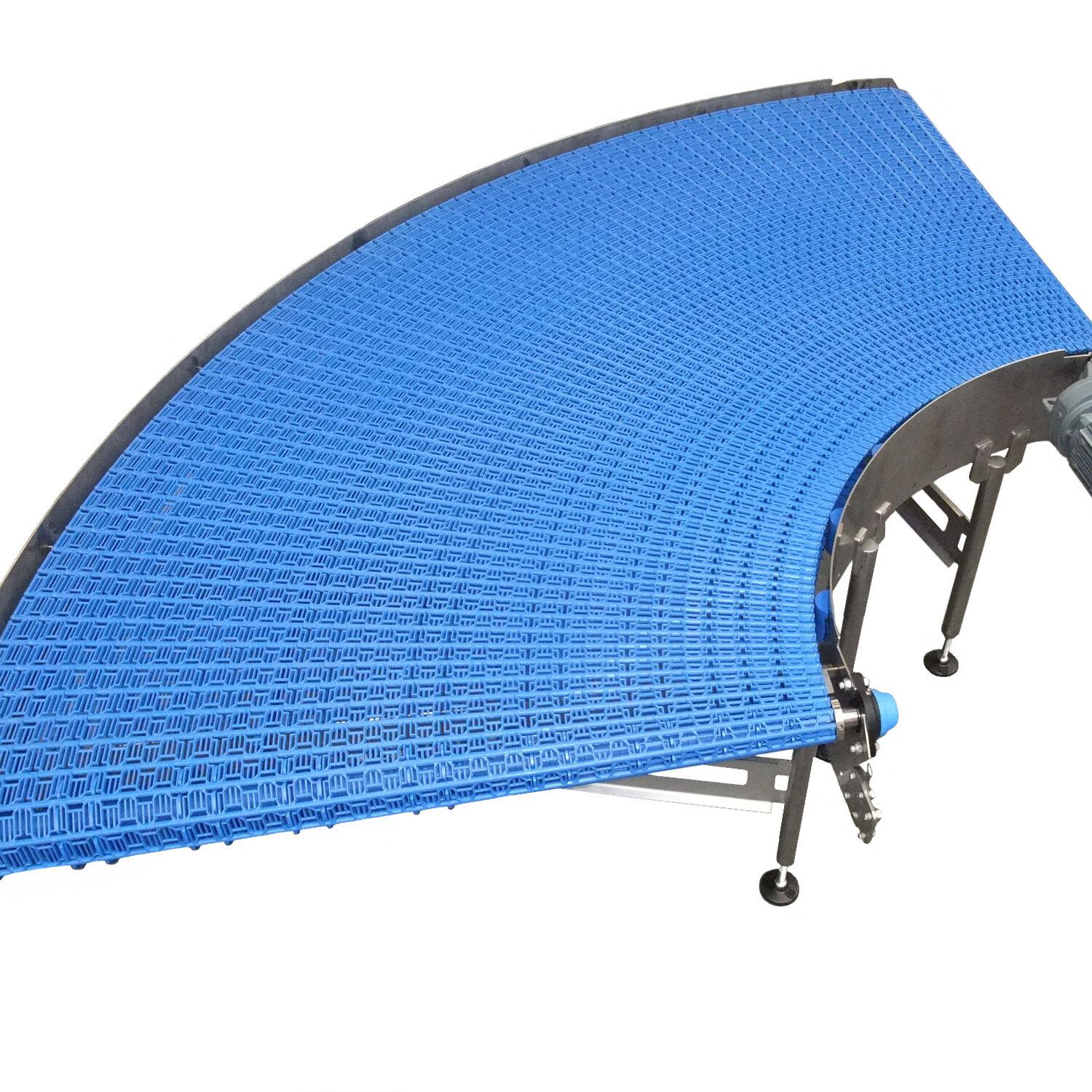

Our standard curved conveyor

Standard curved conveyors are essential for optimizing material handling systems. Designed to transport products smoothly around bends, these conveyors are ideal for various industries, including manufacturing and logistics. Offering reliable performance for lightweight to medium-sized products, standard curved conveyors enhance workflow efficiency and space optimization. Their versatility and smooth transitions make them the perfect solution for facilities aiming to improve productivity and reduce operational downtime in conveyor systems.

Our heavy duty curved conveyor

Heavy-duty curved conveyors are designed to handle large, bulky loads with ease, making them ideal for industrial applications such as automotive, logistics, and manufacturing. These robust conveyors ensure durability and reliability, even under heavy usage, improving productivity and workflow efficiency. With the ability to navigate tight spaces, heavy-duty curved conveyors maximize space optimization while ensuring smooth product handling and seamless integration into your production line or distribution system.

Our hyper hygienic design curved conveyor

The hyper-hygienic curved conveyor is ideal for industries such as pharmaceuticals, food processing, and other sectors where hygiene is critical. Designed with easy-to-clean surfaces and sanitary belts, these conveyors help maintain compliance with hygiene standards while preventing contamination. Their design enhances workflow efficiency and optimizes space utilization, ensuring smooth product flow. Perfect for environments where cleanliness and material handling efficiency are a top priority.

Different dimensions of the curved conveyors.

Curved conveyors come in various dimensions to meet specific operational needs. The width, length, and curve radius of the conveyors can be customized for handling different product sizes and optimizing space efficiency. Belt widths range from 225 mm to 1300 mm, ensuring versatility for various product types. These flexible systems ensure smooth transitions, reduce the need for straight conveyors, and maximize workflow efficiency. Ideal for material handling, curved conveyors are used in industries like manufacturing and logistics, offering seamless integration in diverse facility layouts.

Frequently asked questions about our curved conveyors.

What kind of materials are the belts made of?

The belts are made of POM and PA, on request we can send you the certifications.

What is the max weight the conveyors can handle?

Our conveyors systems are fit for the heavy duty industries, for every situation we could make a calculation for you. We have delivered conveyors who carry a weight of 1000kg plus on them.

In what kind of materials are the conveyors available?

The frame of the conveyor is available in stainless steel 304, on request stainless steel 316 and in steel powder coated in colour as requested by client.

How can we clean the conveyor systems?

This is easily done with a brush or compressed air cleaning.

How long do the belts last?

This is depending on the situation, we have customers in the food industry who have been using the same belts for 10 years. But on the other hand we have belts in very abrasive environments were they “just” last a couple of years.